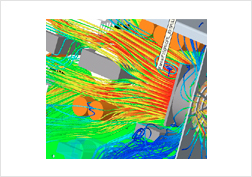

Simulation: Speed and Security for development

Today´s switch-mode power supplies are subject to high integration density and unusual places of operation, resulting in increasingly high power density in relation to the total volume of each power supply, in every conceivable place and under every kind of environmental condition. Only by using the latest development tools and optimised processes can new developments still be realised in terms of time and costs.

Advantage in power supplies development

With the aid of flow simulation, all thermodynamic parameters relating to the system under review can be recorded on a three-dimensional level anytime, anywhere and subsequently evaluated.

This enables developers to monitor key figures relating to both thermodynamics and computational fluid dynamics. Apart from the heat flow in components, it includes above all the flow around components and their reaction to the flow in the power supply itself.

Consequent utilisation: Each step under control

The flow simulation software used by MGV for development work is based on a completely new CFD software concept. Among other things, its 3D CAD models allow for direct simulation of flows and heat transfer without having to previously copy or convert data. This means that allowance can be made for changes at any time during the development phase.

Standard simulations include:

- Flow through and around components

- Incompressible and compressible flow of viscous gases, including subsonic, transonic and supersonic flows

- Rotating parts (rotors, stators), centrifugal and Coriolis forces

- Heat exchange with solids, thermal conduction and convection

- Surface radiation, solar radiation, radiation exchange with the surroundings